Recyclable Coffee Bags

The Green Ambassador of Coffee Bags: How PE & PP Plastics Enable Recycling

— A Practical Guide for Coffee Business Owners

Imagine your carefully roasted coffee beans shipped in glossy bags to customers. After use, those bags may sit in landfills for 500 years. This isn’t science fiction—it’s the harsh reality of traditional coffee packaging. Now, a "mono-material" revolution is sweeping the industry: bags made of pure PE plastic or pure PP plastic are rewriting coffee packaging’s destiny.

Why Traditional Bags Become Recycling "Outcasts"

Cut open a traditional coffee bag, and you’ll find a layer cake:

- Outer layer: Logo-printed plastic (PET)

- Middle layer: Barrier layer-aluminum foil

- Inner layer: Heat-Sealing plastic (PE)

- Bonded with glue

- Printed ink

Recycling plants hate them because:

- Aluminum and plastic can’t be separated

- Glue contaminates recycled materials

- They end up incinerated or buried

Result: 97% of coffee bags end in landfills globally; only 3% are recycled.

Mono-Material Bags: Simplicity Wins

🌱 Core innovation: The entire bag uses ONE plastic!

- PE bags: Flexible like garden hoses (great for moisture resistance)

- PP bags: Rigid like food containers (excellent for structure)

♻️ Simple treatment to recycle

Recycling plants melt pure PE/PP bags directly, like turning old bottles into new ones.

📊 Real case:

German brand Coffee (WILDKAFFEE), Circle boosted recycling rates from 3% to 74% using pure PE bags.

PE vs PP: The Showdown

| Feature | PE (Polyethylene) | PP (Polypropylene) |

| Feel | Soft like kraft paper | Firm like gift wrap |

| Barrier | Moisture-blocking | Oxygen-blocking |

| Weakness | Oxygen intrusion | Brittle below 0°C |

| Ideal for | E-commerce, humid areas | Premium display packaging |

Nano-Armor for Bags

How do we fix freshness gaps? Scientists created three "invisible armors":

Silicon Oxide Coating (for PE bags)

- How: Spray glass-like layer (1/10,000th hair thickness)

- Result: 300x better oxygen blocking (matches aluminum foil)

Aluminum Oxide Coating (for PP bags)

- Bonus: Survives 10,000 bends without cracking

- Proven: 91% aroma retention after 6 months (Japan)

EVOH extruded layer(For PE bags, best option)

- EVOH is like aluminum layer inside the PE.

- Result: best barrier for oxygen and water.

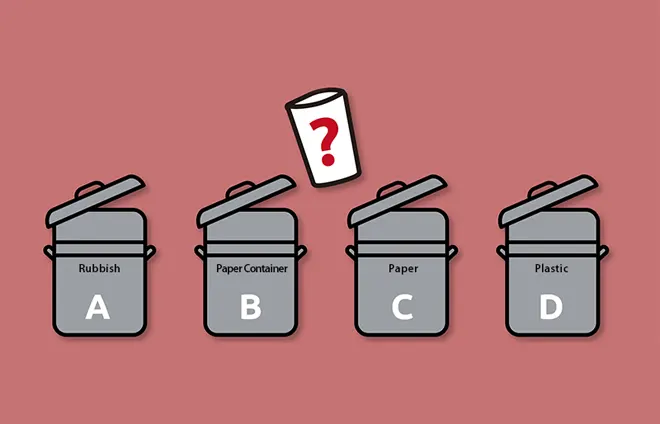

Three Roadblocks to Recycling

Recycling Plant "Face Blindness"

- Issue: Machines misidentify coated bags as trash, hard to separate between the regular bags and recyclable bags.

Regular Material Pretending to Recyclable Material

- Reality: Some compounded (PET/PE) bags are treated as recyclable material, causing a big problem of recycling.

Consumer Confusion

- Myth: "Recyclable = Biodegradable" → Thrown in trash

- Education:

- Print "Toss in ♻️#4/5 Bin!" on bags

- Trade empty bags for discounts (e.g., 3 bags = 1 free americano)

The Business Success

| Cost Item | Traditional | PE Mono Bag |

| Per-bag Cost | $0.20 | $0.26 |

| Recycling Fee | $0 | $0.03 |

| Total | $0.20 | $0.29 |

Upsides:

- Charge 15% more for eco-packaging

- 29% increase in repeat customers

- Avoid EU green penalties (up to $100,000/violation)

Cool Tech Coming Soon

Plastic-to-Oil

Dirty bags → Crude oil → New plastic (2024 pilots)

Smart Freshness Tag

- Turns red if overheated

- Taps phone to show "days since roast"

Air-Made Plastic

PE from captured CO₂ (66% lower carbon footprint)

Small Bag, Big Cycle

When a Germany Coffee Roaster recycles a PE recyclable coffee bag, it may become:

→ A child’s LEGO brick

→ Cafe furniture

→ A new coffee bag

This isn’t just tech upgrade—it’s smarter business:

Good packaging shouldn’t be life’s endpoint,

but a way station in the resource cycle.

Choose PE/PP mono bags. Let every coffee’s scent carry toward a sustainable future.

Build your bag and get a quote

Build your bag and get a quote